Combustion experiments

In the spring of 2017, the Department of Chemical Engineering and Biotechnology relocated to a new building, providing the CoMo group with new laboratories. Since then, these laboratories have been equipped with a number of burners and experimental techniques for fundamental combustion science, research on soot formation during hydrocarbon combustion, and the synthesis of inorganic materials and nanostructured layers. An overview of the facilities and current research areas is given below.

The flame rig was designed and built in-house and is situated inside a walk-in fume hood. It accommodates a co-flow diffusion flame (Yale burner) and a premixed burner of our own design. Both can be fuelled with gaseous or pre-vaporised liquid fuels. In addition, metal-organic precursors can be injected into the fuel stream to synthesis metal oxide nanoparticles. All instruments for operating the flames are controlled and monitored via a LabVIEW graphical user interface. This includes the syringe pumps, mass flow controllers, fuel evaporators, heating elements and thermocouples, and a vertical translational stage.

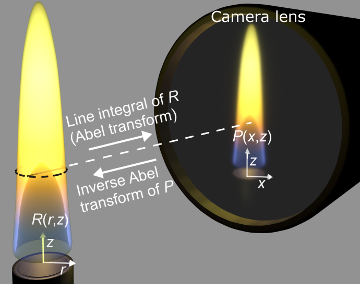

One of the flame characterisation techniques used by our group is colour ratio pyrometry. Here, the colour and intensity of visible light emitted from hot soot particulates is used to infer soot temperatures and volume fractions. A key challenge with this techniques is the computation of the light intensity in the flame R(r,z) from its projection P(x,z) recorded by the camera (inverse Abel transform). Our group developed a new Abel inversion methodology specifically for co-flow diffusion flame images based on fitting the line-of-sight projection of a predefined intensity distribution (FLiPPID) to flame images. Here, a suitable function describing the light intensity in the flame R(r,z) is used and its forward Abel transform is fitted to the experimentally observed data. The advantages of this approach are that it gives a smooth Abel inverse, especially close to the flame centre line, and that it prevents non-physical negative values of the light intensity.

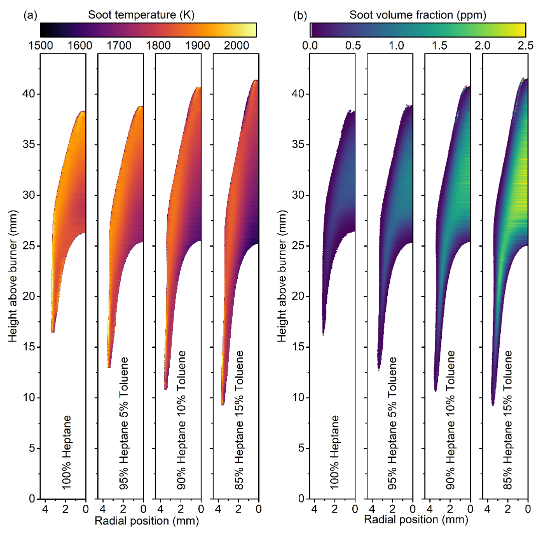

An example of the application of colour ratio pyrometry and the FLiPPID technique is the characterisation of a co-flow diffusion flame fuelled with heptane/toluene mixtures. As can be seen, toluene leads to soot nucleation closer to the burner, an increase in the overall amount of soot and an elongation of the visible flame height because more soot needs to be oxidised. The larger soot volume fraction of the toluene laden flames causes an increase of the radiative heat loss and thus a decrease in the flame temperature. These findings are relevant to the development of modern efficient surrogate fuels.

Another pyrometry-based technique being developed in our group is thin filament pyrometry. For the measurements, a thin silicon carbide (SiC) fibre is placed into the flame and its light emission is measured to infer the fibre temperature. This fibre temperature is then corrected for radiative heat losses to infer the flame gas temperature. The advantage of this technique is that it measures the gas temperature, as opposed to the soot temperature as measured by colour ratio pyrometry. Other advantages of this technique compared to thermocouples are that the small fibre diameter minimises disturbance to the flame, that that temperatures along the fibre line are measured as opposed to the temperature at the thermocouple junction point, and that SiC can used at higher temperatures.

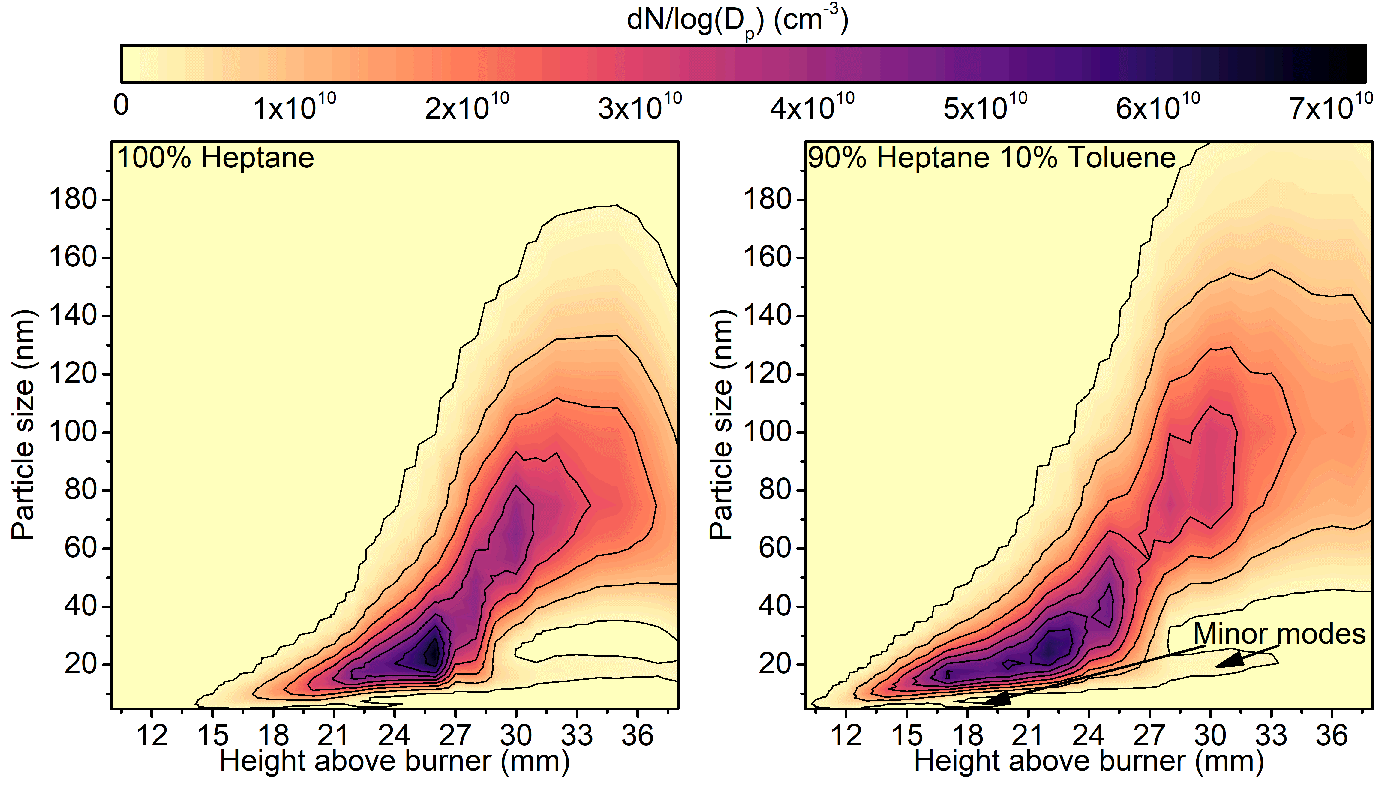

Soot samples from within the diffusion flames are taken using a quartz probe that was developed in-house. The hot flame gases and soot are rapidly mixed with room temperature nitrogen to quench any chemical reactions, to minimise further particle growth and to avoid coagulation of the particles. The quenched aerosol is passed to a Differential Mobility Spectrometer (DMS500) to provide real-time measurement of the soot number density and particle size distribution. The example shown reports the soot particle size distribution along the centre-line of heptane/toluene fuelled co-flow diffusion flames. In agreement with the colour ratio pyrometry, the DMS500 results show an earlier soot nucleation for toluene containing flames, the growth of larger soot particles, and less rapid soot oxidation.

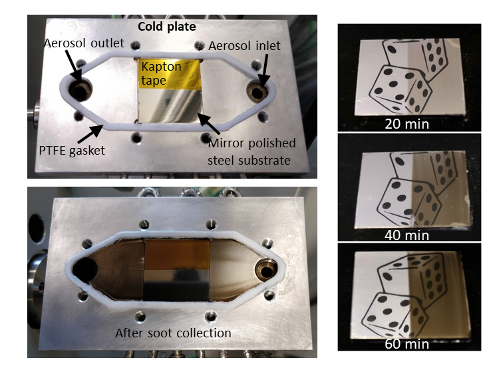

Another technique that has been developed in-house is thermophoretic particle collection. A particle collector is installed in the line from the quartz sample probe to the DMS500. It enables the collection of particle samples that are rapidly quenched and are thus representative of the particles found in the flames. The system is based on a water-cooled bottom plate containing a substrate and a heated top plate. The steep temperature gradient between the hot and cold plate causes particles to deposit on the cold substrate. In the example shown, half of the substrate was masked with Kapton tape during the particle collection to highlight the effect of collection time. As can be seen, the amount of sample that is collected can be controlled by varying the collection time. The collected particles are characterised offline to correlate their physicochemical properties and the flame location from where they were taken.

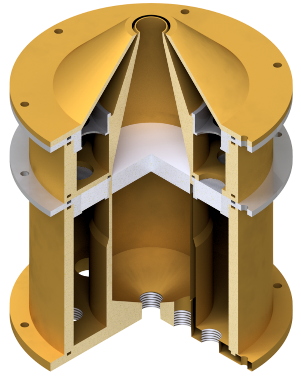

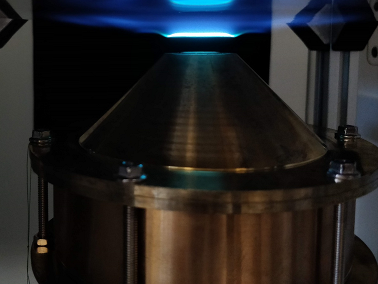

The second burner available in our group was developed in-house and is used for research on pre-mixed flames. The contoured shape of the burner nozzle induces a top-hat velocity profile at the burner exit. A water cooled stagnation plate is placed above the burner, resulting in a thin flat flame. Metal organic precursors can be injected into the premixed gas stream to synthesis metal oxide nanoparticles. These particles are deposited onto substrates mounted on the stagnation plate and can be used to prepare functional nanostructured materials. The flame conditions, such as fuel/air equivalence ratio, flow velocity, or burner-stagnation plate distance can be varied to tune the properties of the as-synthesised materials.

Recent Associated Preprints

298: Influence of the types of oxygenated fuels on the characteristics of soot emitted from a CI engine

Yong Ren Tan, Qiren Zhu, Yichen Zong, Jiawei Lai, Maurin Salamanca, Jethro Akroyd, Wenming Yang, and Markus Kraft, Technical Report 298, c4e-Preprint Series, Cambridge, 2022.

290: Effects of particle collection in a premixed stagnation flame synthesis with a rotating substrate

Manoel Y. Manuputty, Rong Xu, and Markus Kraft, Technical Report 290, c4e-Preprint Series, Cambridge, 2022.

288: Injection of charge from non-thermal plasma into a soot forming laminar coflow diffusion flame

Yong Ren Tan, Yichen Zong, Maurin Salamanca, Jacob W. Martin, Jochen Dreyer, Jethro Akroyd, Wenming Yang, and Markus Kraft, Technical Report 288, c4e-Preprint Series, Cambridge, 2022.

274: How does blending oxygenated fuels affect soot formation from Jet A2 diffusion flames?

Yong Ren Tan, Maurin Salamanca, Jethro Akroyd, and Markus Kraft, Technical Report 274, c4e-Preprint Series, Cambridge, 2021.

Recent Associated Publications

Yong Ren Tan, Qiren Zhu, Yichen Zong, Maurin Salamanca, Jiawei Lai, Jethro Akroyd, Wenming Yang, and Markus Kraft, Fuel 338, 127296, (2023).

Evaluating the effect of n-butanol additive on particulate matter emission in diesel engine

Qiren Zhu, Yichen Zong, Yong Ren Tan, Jieyao Lyu, Wenbin Yu, Wenming Yang, and Markus Kraft, Fuel 332(1), 126003, (2023).

Manoel Y. Manuputty, Rong Xu, and Markus Kraft, Chemical Engineering Science 265, 118155, (2023).

Perspectives for regulating 10 nm particle number emissions based on novel measurement methodologies

Zissis Samaras, Marcus Rieker, Eleni Papaioannou, Willem F. van Dorp, Marina K. Kousoulidou, Leonidas Ntziachristos, Jon Andersson, Alexander Bergmann, Stefan Hausberger, Jorma Keskinen, Panu Karjalainen, Sampsa Martikainen, Athanasios Mamakos, Christoph Haisch, Anastasios Kontses, Zisimos Toumasatos, Lukas Landl, Markus Bainschab, Tero Lähde, Oriana Piacenza, Philipp Kreutziger, Amit Bhave, Kok Foong Lee, Jethro Akroyd, Markus Kraft, Mohsen Kazemimanesh, Adam M. Boies, Cristian Focsa, Dumitru Duca, Yvain Carpentier, Claire Pirim, Jennifer A. Noble, Ophélie Lancry, Sébastien Legendre, Torsten Tritscher, Jürgen Spielvogel, Hans-Georg Horn, Antonio Pérez, Susanna Paz, Dimitrios Zarvalis, Anastasios Melas, Penelope Baltzopoulou, Nickolas D. Vlachos, Leonidas Chasapidis, Danis Deloglou, Emmanouil Daskalos, Apostolos Tsakis, Athanasios G. Konstandopoulos, Stéphane Zinola, Silvana Di Iorio, Francesco Catapano, Bianca M. Vaglieco, Heinz Burtscher, Giovanna Nicol, Daoíz Zamora, and Maurizio Maggiore, Journal of Aerosol Science 162, 105957, (2022).

Funding

This research was partly funded by the National Research Foundation (NRF), Prime Minister's Office, Singapore under its Campus for Research Excellence and Technological Enterprise (CREATE) programme.