Engine Research

Increasingly stringent and restrictive legislation on vehicle emissions provides a compelling impetus for the development of cleaner internal combustion (IC) engines. Furthermore, the robustness, the relatively cheap cost and the adaptability to alternative fuels make advanced IC engines a practical mid-term solution for powertrain applications.

The CoMo Groups's engine research is focussed on the development of sophisticated computational models to simulate conventional as well as advanced combustion modes in IC engines. A wide range of modeling approaches and applications are being continuously developed and improved.

For instance, a detailed evolution of engine-out emissions, combustion characteristics and engine performance parameters within practical simulation times can be obtained using a probability density function (PDF)-based stochastic reactor model (SRM). The SRM accounts for inhomogeneities in composition and temperature arising from various processes occurring in an engine cylinder, for example, direct and port fuel injection, convective heat transfer, and turbulent mixing. The model also includes detailed chemical kinetics description which is of particular importance given the dominating role played by fuel and combustion chemistry in futuristic combustion modes such as homogeneous charge compression ignition (HCCI).

SRM calculation: Temporal evolution of temperature-equivalence ratio in a Cummins B-series engine

The Figure above shows the PDF describing the temporal evolution of temperature against equivalence ratio in an HCCI engine, as calculated by the CoMo stochastic reactor model.

- Higher local equivalence ratio due to direct injection at -40 CAD ATDC in a lean air-fuel charge;

- Decrease in the local temperature due to evaporative cooling followed by rapid increase in local temperatures due to auto-ignition;

- Turbulent mixing accounts for localness in composition space.

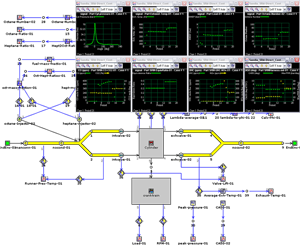

Real time simulation: SRM coupled with GT-PowerTM.

In the case of real-time applications (e.g. engine control, transient simulations) a tabulation approach based on the SRM can be utilized. The engine performance, emissions and combustion parameters can be calculated on a cycle-to-cycle basis.

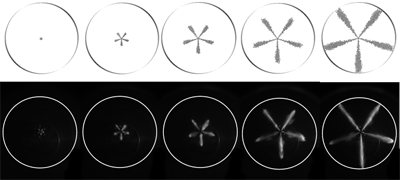

On the other hand, to achieve detailed flow-related description (e.g. turbulent kinetic energy and dissipation information to be utilised in the SRM), multi-dimensional engine modeling is studied using CFD tools such as KIVATM and Star-CDTM. The main thrust of the research activities in this area is related to understanding the distribution of parameters of interest, geometry influences, and sub-models to account for turbulent combustion and emissions formation.

The engine research activities in the CoMo group benefit immensely from the other research areas in the group. For instance, the numerical method development related to quantum chemistry provides important insight into the elementary reaction rate data used to describe the detailed chemical kinetics within the SRM. The work carried out towards simulating laminar and turbulent flames also proves to be an ideal test bed for investigating the many turbulence and reaction closure problems intrinsic to combustion engines.

Simulated spray evolution (top) and comparison with laser measurements (bottom). The comparisons shown are at (left to right): 0.21 ms, 0.35 ms, 0.41 ms, 0.53 ms and 0.59 ms after injection.

There is a considerable commercial interest in the IC engine work carried out in the CoMo Group. Toyota Motor Corp. and Saudi Aramco Oil Company have been actively providing funding to support the development. CMCL Innovations, an R&D-driven SME has been sponsoring PhD studentships in the CoMo Group to advance the simulation technologies in this area of research.

Recent Associated Preprints

298: Influence of the types of oxygenated fuels on the characteristics of soot emitted from a CI engine

Yong Ren Tan, Qiren Zhu, Yichen Zong, Jiawei Lai, Maurin Salamanca, Jethro Akroyd, Wenming Yang, and Markus Kraft, Technical Report 298, c4e-Preprint Series, Cambridge, 2022.

Chung Ting Lao, Jethro Akroyd, and Markus Kraft, Technical Report 291, c4e-Preprint Series, Cambridge, 2022.

Jiaru Bai, Rory M Geeson, Feroz Farazi, Sebastian Mosbach, Jethro Akroyd, Eric J. Bringley, and Markus Kraft, Technical Report 262, c4e-Preprint Series, Cambridge, 2020.

259: Modelling investigation of the thermal treatment of ash-contaminated particulate filters

Chung Ting Lao, Jethro Akroyd, Alastair Smith, Neal M. Morgan, Kok Foong Lee, Daniel Nurkowski, and Markus Kraft, Technical Report 259, c4e-Preprint Series, Cambridge, 2020.

Recent Associated Publications

Yong Ren Tan, Qiren Zhu, Yichen Zong, Maurin Salamanca, Jiawei Lai, Jethro Akroyd, Wenming Yang, and Markus Kraft, Fuel 338, 127296, (2023).

Mutian Ma, Laura-Hélèna Rivellini, Nethmi Kasthuriarachchi, Qiren Zhu, Yichen Zong, Wenbin Yu, Wenming Yang, Markus Kraft, and Alex K.Y. Lee, Atmospheric Environment: X 18, 100216, (2023).

Modelling treatment of deposits in particulate filters for internal combustion emissions

Chung Ting Lao, Jethro Akroyd, and Markus Kraft, Progress in Energy and Combustion Science 96, 101043, (2023).

Evaluating the effect of n-butanol additive on particulate matter emission in diesel engine

Qiren Zhu, Yichen Zong, Yong Ren Tan, Jieyao Lyu, Wenbin Yu, Wenming Yang, and Markus Kraft, Fuel 332(1), 126003, (2023).

Funding

Funding has generously been provided by Saudi Aramco, Toyota, CMCL Innovations, EU, Shell, Ford, Lotus, Caterpillar, and BP.