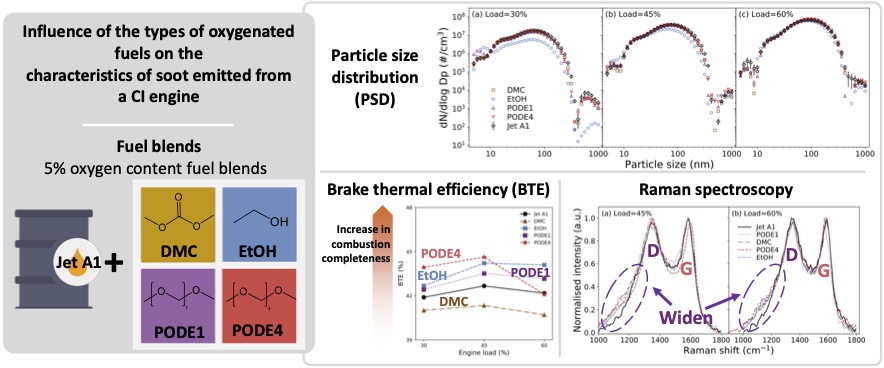

The influence of alcohol, carbonate and polyethers as oxygenated fuels on the soot characteristics from a CI engine

- Blending PODE4 in Jet A1 can increase CI engine BTE by up to 4.8% at engine load 30%.

- Soot from EtOH in Jet A1 had the greatest reduction in average particle size, at 19.6%.

- Soot samples from oxygenated fuels especially PODE1 are more reactive and disordered.

- DMC decomposes into CO2, reducing its effectiveness in soot average particle size reduction.

- EtOH, which produces OH radicals, showed a great increase in nucleation mode particles.

Dimethyl carbonate (DMC), ethanol (EtOH), polyoxymethylene dimethyl ether 1 (PODE1) and polyoxymethylene dimethyl ether 4 (PODE4) were blended with Jet A1 into fuel blends with 5% oxygen content to investigate the effect of the oxygenated fuels on the soot produced by a compression ignition engine. Particle size distribution (PSD) was measured using a differential mobility spectrometer. Thermogravimetric analysis (TGA), Raman spectroscopy, ultraviolet–visible spectroscopy (UV–Vis) and Fourier transform infrared (FT-IR) spectroscopy were performed on the soot collected from the engine. The addition of EtOH, PODE1 improves brake thermal efficiency (BTE) by up to 4.5%, while DMC reduces BTE by 0.9–1.5% compared to Jet A1. EtOH fuel blends have the shortest combustion duration (10.0 deg), followed by PODE1, DMC and PODE4. EtOH blends also have the highest heat release rate peak (4–14% higher than Jet A1). This, combined with improved premixing of EtOH fuel blend in the engine improves the combustion and reduces soot growth. PSD measurements showed that the addition of EtOH significantly reduces accumulation mode particle number concentrations by up to 70 % but promotes the formation of nucleation mode particles. Meanwhile, TGA revealed that the soot from oxygenated fuel blends oxidises at a lower temperature than Jet A1. Notably, PODE1 exhibited a reduction of 54°C in the starting oxidation temperature, which is the largest reduction among the oxygenated fuel blends. Lastly, the conjugation length of the soot aromatic structure for the organic carbons (derived from the optical band gap of UV–Vis) is up to 11% greater for the oxygenated fuel blends, indicating that oxygenated fuel blends promote organic carbon formation. The blending of oxygenated fuels in influencing the soot properties through the dilution effect, combustion condition effect and chemical effect is then critically assessed.

Dimethyl carbonate (DMC), ethanol (EtOH), polyoxymethylene dimethyl ether 1 (PODE1) and polyoxymethylene dimethyl ether 4 (PODE4) were blended with Jet A1 into fuel blends with 5% oxygen content to investigate the effect of the oxygenated fuels on the soot produced by a compression ignition engine. Particle size distribution (PSD) was measured using a differential mobility spectrometer. Thermogravimetric analysis (TGA), Raman spectroscopy, ultraviolet–visible spectroscopy (UV–Vis) and Fourier transform infrared (FT-IR) spectroscopy were performed on the soot collected from the engine. The addition of EtOH, PODE1 improves brake thermal efficiency (BTE) by up to 4.5%, while DMC reduces BTE by 0.9–1.5% compared to Jet A1. EtOH fuel blends have the shortest combustion duration (10.0 deg), followed by PODE1, DMC and PODE4. EtOH blends also have the highest heat release rate peak (4–14% higher than Jet A1). This, combined with improved premixing of EtOH fuel blend in the engine improves the combustion and reduces soot growth. PSD measurements showed that the addition of EtOH significantly reduces accumulation mode particle number concentrations by up to 70 % but promotes the formation of nucleation mode particles. Meanwhile, TGA revealed that the soot from oxygenated fuel blends oxidises at a lower temperature than Jet A1. Notably, PODE1 exhibited a reduction of 54°C in the starting oxidation temperature, which is the largest reduction among the oxygenated fuel blends. Lastly, the conjugation length of the soot aromatic structure for the organic carbons (derived from the optical band gap of UV–Vis) is up to 11% greater for the oxygenated fuel blends, indicating that oxygenated fuel blends promote organic carbon formation. The blending of oxygenated fuels in influencing the soot properties through the dilution effect, combustion condition effect and chemical effect is then critically assessed.

- This paper draws from preprint 298: Influence of the types of oxygenated fuels on the characteristics of soot emitted from a CI engine

- Access the article at the publisher: DOI: 10.1016/j.fuel.2022.127296