Homogeneous Charge Compression Ignition

HCCI operating window - knock, partial burn, and misfire

Homogeneous Charge Compression Ignition (HCCI) is an advanced futuristic combustion technology for internal combustion (IC) engines. HCCI engine technology offers high thermal efficiencies and low NOX and particulate matter (PM) emissions. Similar to spark ignition (SI) engines, the charge is premixed thus reducing the PM emissions, and as in compression ignition direct injection (CIDI) engines, the charge is compression-ignited. However, unlike these conventional modes of operation, the combustion occurs simultaneously at multiple sites throughout the volume with shorter combustion duration and is controlled primarily by chemical kinetics. Various acronyms such as UNIBUS, MK, CAI, PCCI, CCS etc. have been used to explain HCCI-ish combustion modes and have been investigated with conventional as well as alternative fuels. These technologies are also being rigorously tested on a wide size-range of engines applied to transportation and stationary applications.

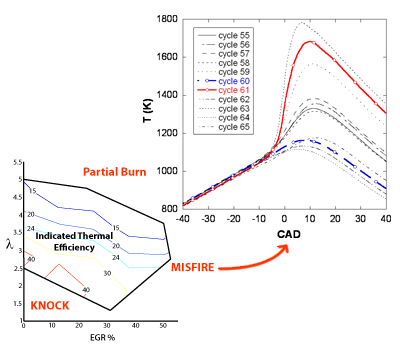

On account of the technical hurdles in terms of a narrow operating window and difficulty in controlling the combustion, HCCI technology demonstration has been limited to dual mode engine operation where the conventional combustion modes are employed at low and high loads, and HCCI is implemented at part loads (e.g., GM, Daimler etc.).

The stochastic reactor model (SRM) developed at the CoMo Group has been applied to investigate various problems facing HCCI engine technology developers.

Wall impingement in early DI PCCI engine

A stable HCCI operating range has been evaluated using the SRM-based full cycle simulation. In particular, the cycle to cycle variation in the in-cylinder combustion characteristics (and hence the emissions and engine performance) on account of intolerable amounts of cooled external exhaust gas recirculation (EGR) was assessed.

Studies were also carried out to understand the role of multiple direct injection in controlling as well as expanding the operating window of the HCCI engine. For gasoline fuelled HCCI operation, strategies such as trapping residual burnt fractions using negative valve overlap (NVO) and direct injection during NVO are being investigated from the point of view of dual mode SI-HCCI-SI engine operation. For Diesel fuelled premixed charge compression ignition (PCCI) engine, dual injection was applied to understand the role of stratification in extending the operating boundary towards idle. In particular, CFD simulations are used to extract statistical information related to phenomena such as wall impingement and mixture formation which is then utilised in the SRM.

Injection of Hydrogen to control combustion - CA50

In addition to the conventional fuels alternative fuels such as natural gas, biogas, hydrogen, ethanol etc. also so potential for HCCI-ish technologies. For instance, the combined combustion system (CSS) demonstrated by Volkswagen merges the merits of SI and CIDI technologies together using synthetic fuel produced from industrial and forest waste.

The CoMo Group is also involved in assessing the effects of additives such as diethyl ether (DEE), hydrogen etc. towards control of HCCI engines.