Liquid-liquid Extraction

Liquid-liquid extraction is applied in many chemical, pharmaceutical and nuclear industries. In order to achieve efficient mass and energy transport and good fluid mixing these processes are often operated in mechanically agitated turbulent flows. The dynamics of these systems are dictated by interphase mass, momentum and energy transfer, size distribution of the bubbles/droplets, and generation of turbulence by the dispersed phase.

If the volume fraction of the dispersed phase is not small, breakage, collision and coalescence of the bubbles/droplets, becomes the factor of paramount importance that determines not only size distribution of the dispersed phase but the main hydrodynamical features of both phases. Thus, any adequate computational fluid dynamics (CFD) description of these flows must incorporate droplets population balance as a submodel.

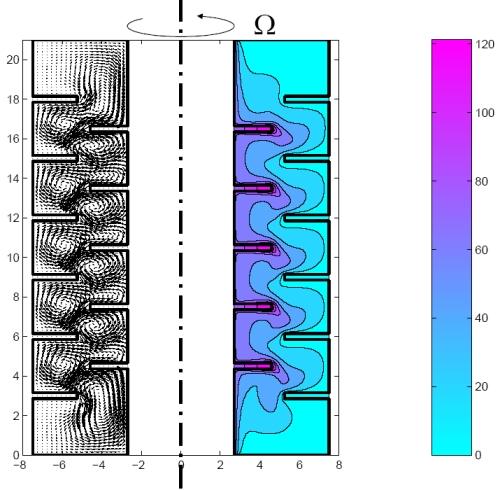

Rotating disc contactor (RDC) has been chosen as an example of mechanically agitated extraction column.

|

| Rotating Disc Contactor (Simulation by A. Vikhansky) |

Our approach is based on:

- k-e Reynolds-averaged Navier-Stokes equations for the continuous phase.

- Iterative two-way interphase coupling.

- Stochastic Lagrange tracking of the dispersed phase.

- Operator-splitting Monte Carlo stochastic simulation of coagulation/fragmentation processes.