Technical Report 242, c4e-Preprint Series, Cambridge

Study of industrial titania synthesis using a hybrid particle-number and detailed particle model

Reference: Technical Report 242, c4e-Preprint Series, Cambridge, 2019

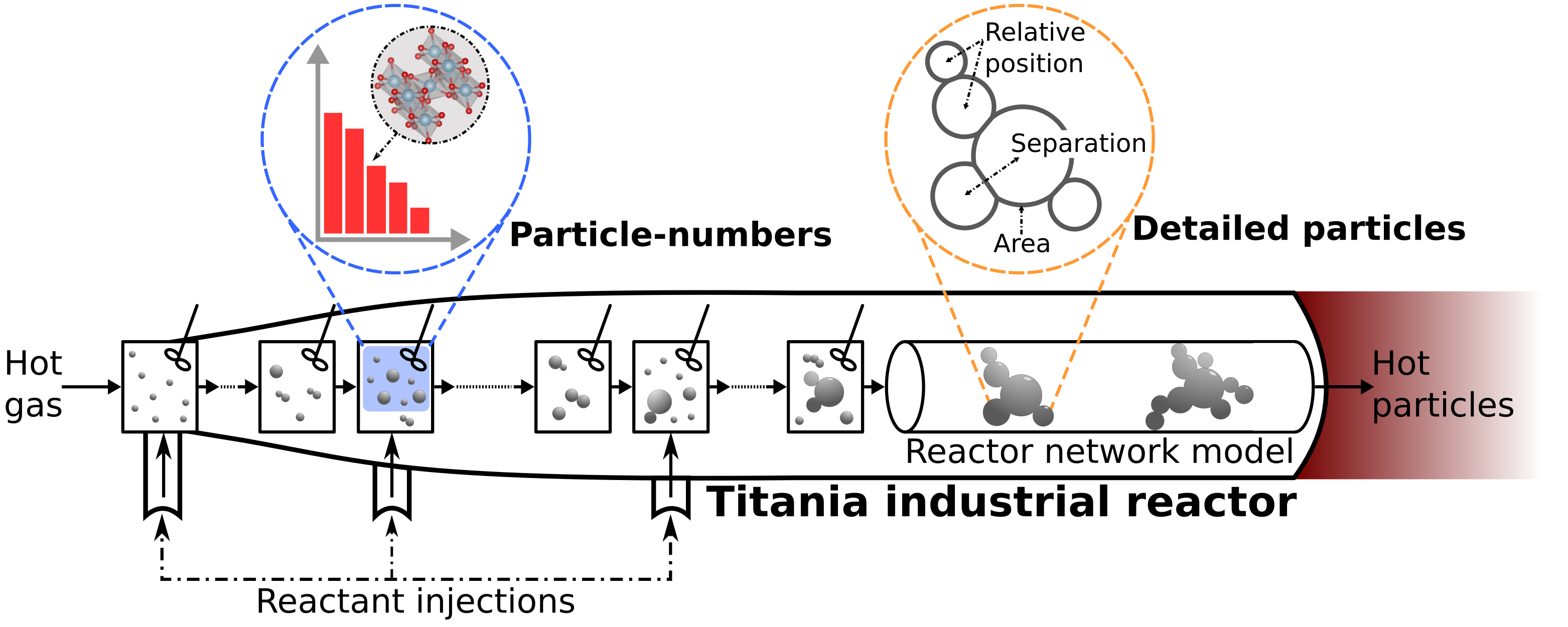

- Hybrid particle model combined with overlapping spheres detailed particle model

- Robust and efficient hybrid approach used to study industrially relevant conditions

- Energy balance included to allow flexible reactor modelling framework

- Particle structure resolved by primary coordinate tracking compared with real product

We apply a hybrid particle model to study synthesis of particulate titania under representative industrial conditions. The hybrid particle model employs a particle-number description for small particles, and resolves complicated particle morphology where required using a detailed particle model. This enables resolution of particle property distributions under fast process dynamics. Robustness is demonstrated in a network of reactors used to simulate the industrial process. The detailed particle model resolves properties of the particles that determine end-product quality and post-processing efficiency, including primary particle size and degree of aggregate cohesion. Sensitivity of these properties to process design choices is quantified, showing that higher temperature injections produce more sintered particles; more frequent injections narrow the geometric standard deviation of primary particle diameter; and chlorine dilution reduces particle size and size variance. Structures of a typical industrial particle are compared visually with simulated particles, illustrating similar aggregate features with slightly larger primary particles.

We apply a hybrid particle model to study synthesis of particulate titania under representative industrial conditions. The hybrid particle model employs a particle-number description for small particles, and resolves complicated particle morphology where required using a detailed particle model. This enables resolution of particle property distributions under fast process dynamics. Robustness is demonstrated in a network of reactors used to simulate the industrial process. The detailed particle model resolves properties of the particles that determine end-product quality and post-processing efficiency, including primary particle size and degree of aggregate cohesion. Sensitivity of these properties to process design choices is quantified, showing that higher temperature injections produce more sintered particles; more frequent injections narrow the geometric standard deviation of primary particle diameter; and chlorine dilution reduces particle size and size variance. Structures of a typical industrial particle are compared visually with simulated particles, illustrating similar aggregate features with slightly larger primary particles.

Material from this preprint has been published in Chemical Engineering Science.

PDF (10.1 MB)