Technical Report 195, c4e-Preprint Series, Cambridge

Analysing the effect of screw configuration using a stochastic twin-screw granulation model

Reference: Technical Report 195, c4e-Preprint Series, Cambridge, 2018

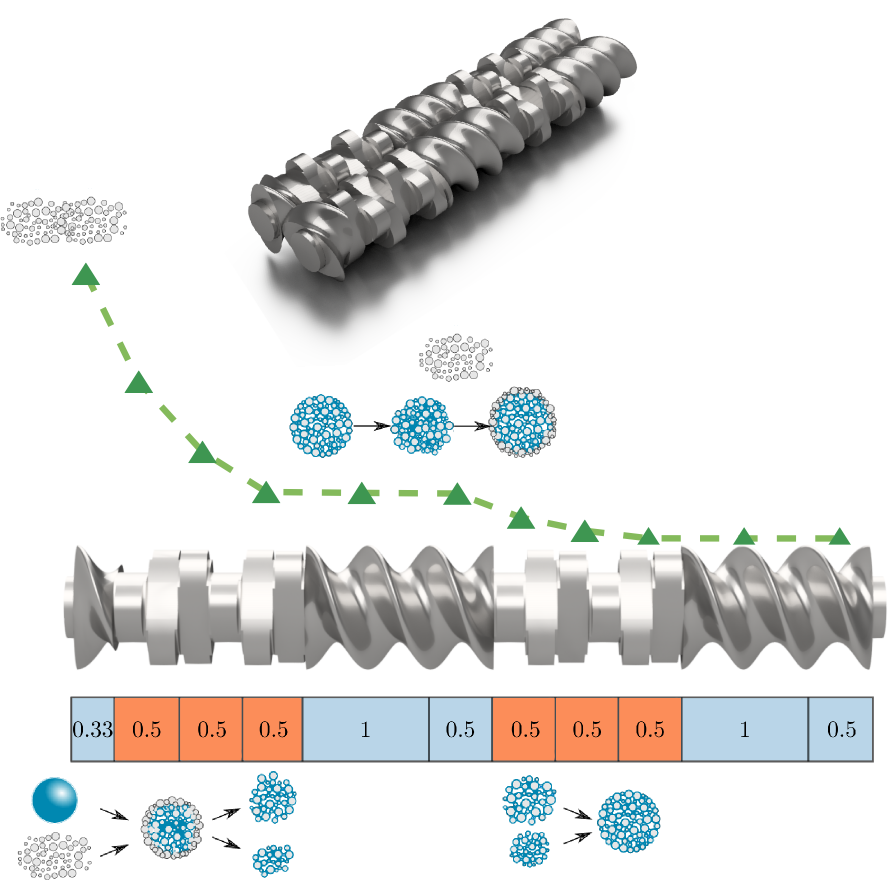

- Existing model extended to include novel layering mechanism

- Novel compartment residence time model developed

- New breakage model reflects screw element geometry effects

- Model captures the liquid distributing/growth promoting effects of kneading elements

In this work we present a framework for modelling twin-screw granulation processes with variable screw configurations using a high-dimensional stochastic population balance method. A modular compartmental approach is presented and a method for estimating residence times for model compartments based on screw element geometry is introduced. The model includes particle mechanisms for nucleation, primary particle layering, coalescence, breakage, and consolidation. We introduce a new twin-screw breakage model which takes into account the differing breakage dynamics between two types of screw element. The resulting model is used to simulate a twin-screw system with a number of different screw configurations and the predictive power of the model is assessed through comparison with an existing experimental data set in the literature. The model demonstrates the ability to qualitatively capture experimental trends, including the reduction in fines associated with an increase in the number of kneading elements in the screw configuration. Based on model results, a number of key areas for future model development are identified and discussed.

In this work we present a framework for modelling twin-screw granulation processes with variable screw configurations using a high-dimensional stochastic population balance method. A modular compartmental approach is presented and a method for estimating residence times for model compartments based on screw element geometry is introduced. The model includes particle mechanisms for nucleation, primary particle layering, coalescence, breakage, and consolidation. We introduce a new twin-screw breakage model which takes into account the differing breakage dynamics between two types of screw element. The resulting model is used to simulate a twin-screw system with a number of different screw configurations and the predictive power of the model is assessed through comparison with an existing experimental data set in the literature. The model demonstrates the ability to qualitatively capture experimental trends, including the reduction in fines associated with an increase in the number of kneading elements in the screw configuration. Based on model results, a number of key areas for future model development are identified and discussed.

Material from this preprint has been published in Chemical Engineering Science.

PDF (4.9 MB)