A high-dimensional, stochastic model for twin-screw granulation - Part 1: Model description

- A novel, four-dimensional population balance model for twin-screw granulation is presented.

- Particle compositions are resolved along the screw barrel.

- The model's performance is assessed at different liquid-solid feed ratios using experimental data.

- We observe qualitative agreement with experimental trends.

- The model framework can be readily extended to higher dimensions.

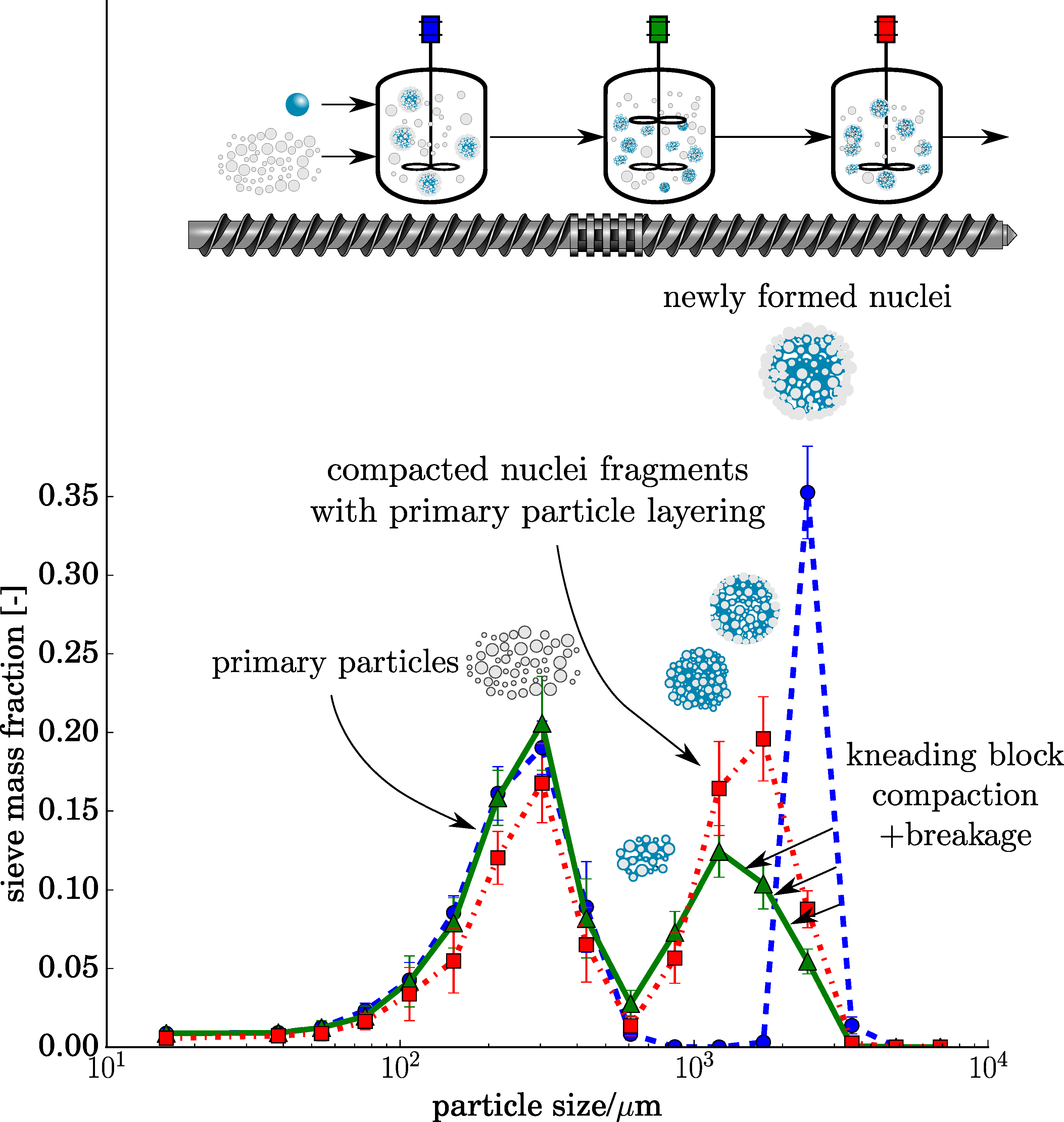

In this work we present a novel four-dimensional, stochastic population balance model for twin-screw granulation. The model uses a compartmental framework to reflect changes in mechanistic rates between different screw element geometries. This allows us to capture the evolution of the material along the barrel length. The predictive power of the model is assessed across a range of liquid-solid feed ratios through comparison with experimental particle size distributions. The model results show a qualitative agreement with experimental trends and a number of areas for model improvement are discussed. A sensitivity analysis is carried out to assess the effect of key operating variables and model parameters on the simulated product particle size distribution. The stochastic treatment of the model allows the particle description to be readily extended to track more complex particle properties and their transformations.

In this work we present a novel four-dimensional, stochastic population balance model for twin-screw granulation. The model uses a compartmental framework to reflect changes in mechanistic rates between different screw element geometries. This allows us to capture the evolution of the material along the barrel length. The predictive power of the model is assessed across a range of liquid-solid feed ratios through comparison with experimental particle size distributions. The model results show a qualitative agreement with experimental trends and a number of areas for model improvement are discussed. A sensitivity analysis is carried out to assess the effect of key operating variables and model parameters on the simulated product particle size distribution. The stochastic treatment of the model allows the particle description to be readily extended to track more complex particle properties and their transformations.

- This paper draws from preprint 191: A high-dimensional, stochastic model for twin-screw granulation - Part 1: Model description

- Access the article at the publisher: DOI: 10.1016/j.ces.2018.04.076