Characterisation of lactose powder and granules for multivariate wet granulation modelling

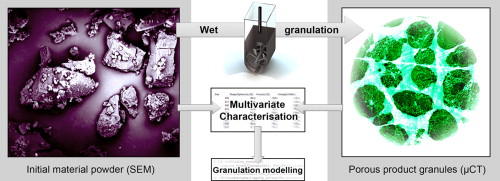

- Multivariate data for lactose and its wet granulation product granules are reported.

- Measured properties are granule size, porosity, surface structure and strength.

- The data were used to improve a multivariate population balance granulation model.

- The 5-dimensional model was solved using a Monte Carlo method.

Granulation and size enlargement of particulate materials is a complex process with broad application in industry. For better understanding of the governing mechanisms, we aim to develop a multivariate population balance model to describe granulation. For meaningful model design we require physical characteristics of real materials undergoing granulation. In this work, α-lactose monohydrate powder was investigated as a representative substance due to its broad use in the pharmaceutical industry for tablets. Powder and granules resulting from a high-shear granulation process are characterized with respect to size, shape, porosity and strength using various analytical methods. Particle size distributions are obtained by static image analysis, laser scattering and sieving. Granule porosities are determined using μ CT and mercury intrusion porosimetry. Lactose granules show absolute porosities increasing from 30% to 40% along the size classes. The μ CT derived visual information of larger granules shows internal pore structures with denser cores and porous shell parts. AFM, SEM and μ CT are used for surface characterisation, yielding a maximum value for model particle roughness up to 0.7μm source. The strength of the product granules measured via uniaxial compression testing follows a logarithmic decrease with size from 1.2 to 0.2 MPa. The multivariate data set was then used for model performance analysis and parameter fitting. The size and porosity prediction performance of the computer model could be improved using the newly available data. The rate of coagulation was found to be the most dominant simulation parameter. Comparison with the experiment revealed limitations, for example in PSD shape predictions.

Granulation and size enlargement of particulate materials is a complex process with broad application in industry. For better understanding of the governing mechanisms, we aim to develop a multivariate population balance model to describe granulation. For meaningful model design we require physical characteristics of real materials undergoing granulation. In this work, α-lactose monohydrate powder was investigated as a representative substance due to its broad use in the pharmaceutical industry for tablets. Powder and granules resulting from a high-shear granulation process are characterized with respect to size, shape, porosity and strength using various analytical methods. Particle size distributions are obtained by static image analysis, laser scattering and sieving. Granule porosities are determined using μ CT and mercury intrusion porosimetry. Lactose granules show absolute porosities increasing from 30% to 40% along the size classes. The μ CT derived visual information of larger granules shows internal pore structures with denser cores and porous shell parts. AFM, SEM and μ CT are used for surface characterisation, yielding a maximum value for model particle roughness up to 0.7μm source. The strength of the product granules measured via uniaxial compression testing follows a logarithmic decrease with size from 1.2 to 0.2 MPa. The multivariate data set was then used for model performance analysis and parameter fitting. The size and porosity prediction performance of the computer model could be improved using the newly available data. The rate of coagulation was found to be the most dominant simulation parameter. Comparison with the experiment revealed limitations, for example in PSD shape predictions.

- This paper draws from preprint 132: Multivariate characterisation of lactose powder and granules of a wet granulation process

- Access the article at the publisher: DOI: 10.1016/j.ces.2014.11.013