Technical Report 184, c4e-Preprint Series, Cambridge

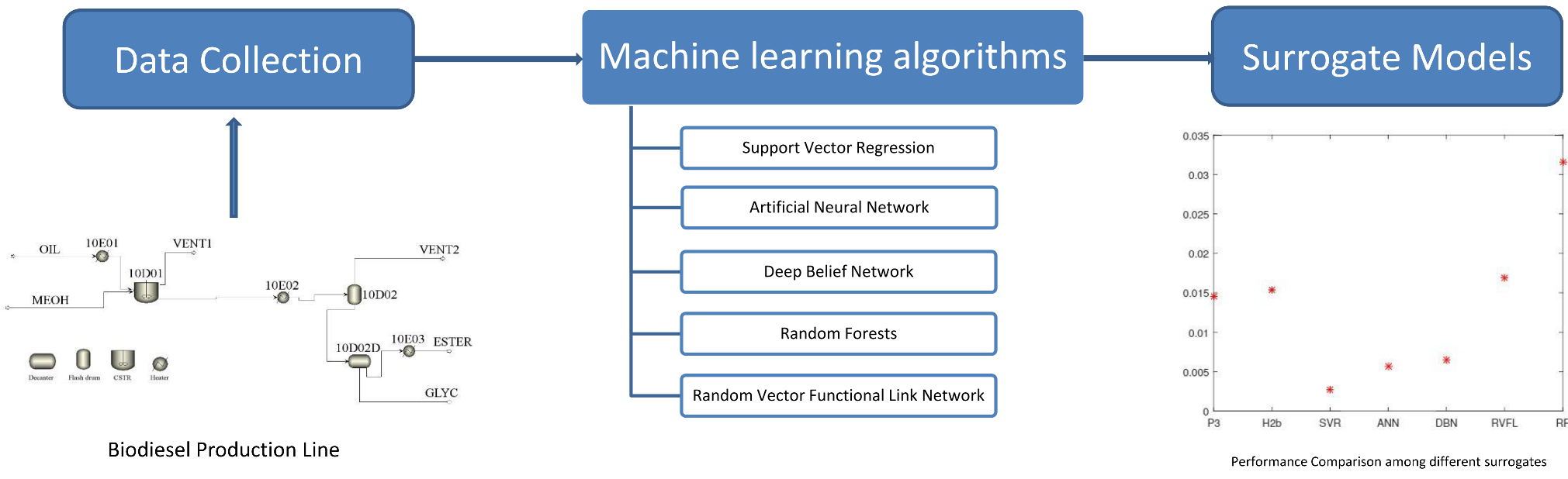

Machine learning approach for constructing surrogates of a biodiesel plant flow sheet model

Reference: Technical Report 184, c4e-Preprint Series, Cambridge, 2017

- Input-output relations within process flowsheet of a biodiesel plant are analyzed.

- Various machine learning algorithms are employed for constructing surrogate models.

- A variety of scenarios are considered including four input dimensions and five surrogates.

- Polynomial response surface fitting and high dimensional model representation are compared with machine learning methods.

- The simulation results show the effectiveness and efficiency of machine learning methods.

In this work, a process flowsheet of biodiesel plant is used to construct surrogate

models by various machine learning methods. For this paradigm, we approximate the

heat duties of various units in the flowsheet by varying 1,2,6 and 11 input variables.

We use 3 domain sizes of input variables, and 5 different surrogates namely support vector regression (SVR), artificial neural network (ANN), deep belief network

(DBN), random forests (RF), and random vector functional link network (RVFL). A

comparison among polynomial response surface fitting, high dimensional model representation (HDMR) and machine learning models is performed based on three error

measures namely root-mean-squared-deviation (RMSD), R2 and residuals. Moreover, the efficiency of learning methods is compared based on their computational

expense and some statistical measure. The simulation results show the attractiveness

of machine learning methods for constructing surrogate models in context of process

simulation.

In this work, a process flowsheet of biodiesel plant is used to construct surrogate

models by various machine learning methods. For this paradigm, we approximate the

heat duties of various units in the flowsheet by varying 1,2,6 and 11 input variables.

We use 3 domain sizes of input variables, and 5 different surrogates namely support vector regression (SVR), artificial neural network (ANN), deep belief network

(DBN), random forests (RF), and random vector functional link network (RVFL). A

comparison among polynomial response surface fitting, high dimensional model representation (HDMR) and machine learning models is performed based on three error

measures namely root-mean-squared-deviation (RMSD), R2 and residuals. Moreover, the efficiency of learning methods is compared based on their computational

expense and some statistical measure. The simulation results show the attractiveness

of machine learning methods for constructing surrogate models in context of process

simulation.

PDF (1.5 MB)