Technical Report 160, c4e-Preprint Series, Cambridge

Skeletal chemical mechanism of high-temperature TEOS oxidation in hydrogen-oxygen environment.

Reference: Technical Report 160, c4e-Preprint Series, Cambridge, 2015

- A skeletal mechanism describing TEOS oxidation in flames is proposed.

- A three-stage reduction is used to eliminate unimportant species and reactions.

- Rate parameters for the main TEOS decomposition pathways are refined using transition state theory.

- Energetics of the key reaction channels is improved using CBS-Q method.

This paper improves the tetraethoxysilane (TEOS) oxidation mechanism proposed

by Nurkowski et al. (Proc. Comb. Inst., 35:2291-2298, 2015) by refining the rate parameters

of the key reaction channels in the mechanism. A skeletal version of the mechanism

is proposed for hydrogen-oxygen environment. The rates of ethylene-loss from

(tetra-, tri-, di- and dimethyldi-) ethoxysilane are computed using transition state theory.

The energetics of the main pathways are refined by performing detailed ab initio

calculations using the CBS-Q technique. An analysis of ethanol formation via silicates

is also performed resulting in the addition of 27 new silica species to the model. Thermodynamic

properties for these species are calculated via the balanced reactions method.

Reasonably good agreement between the improved model and available experimental data

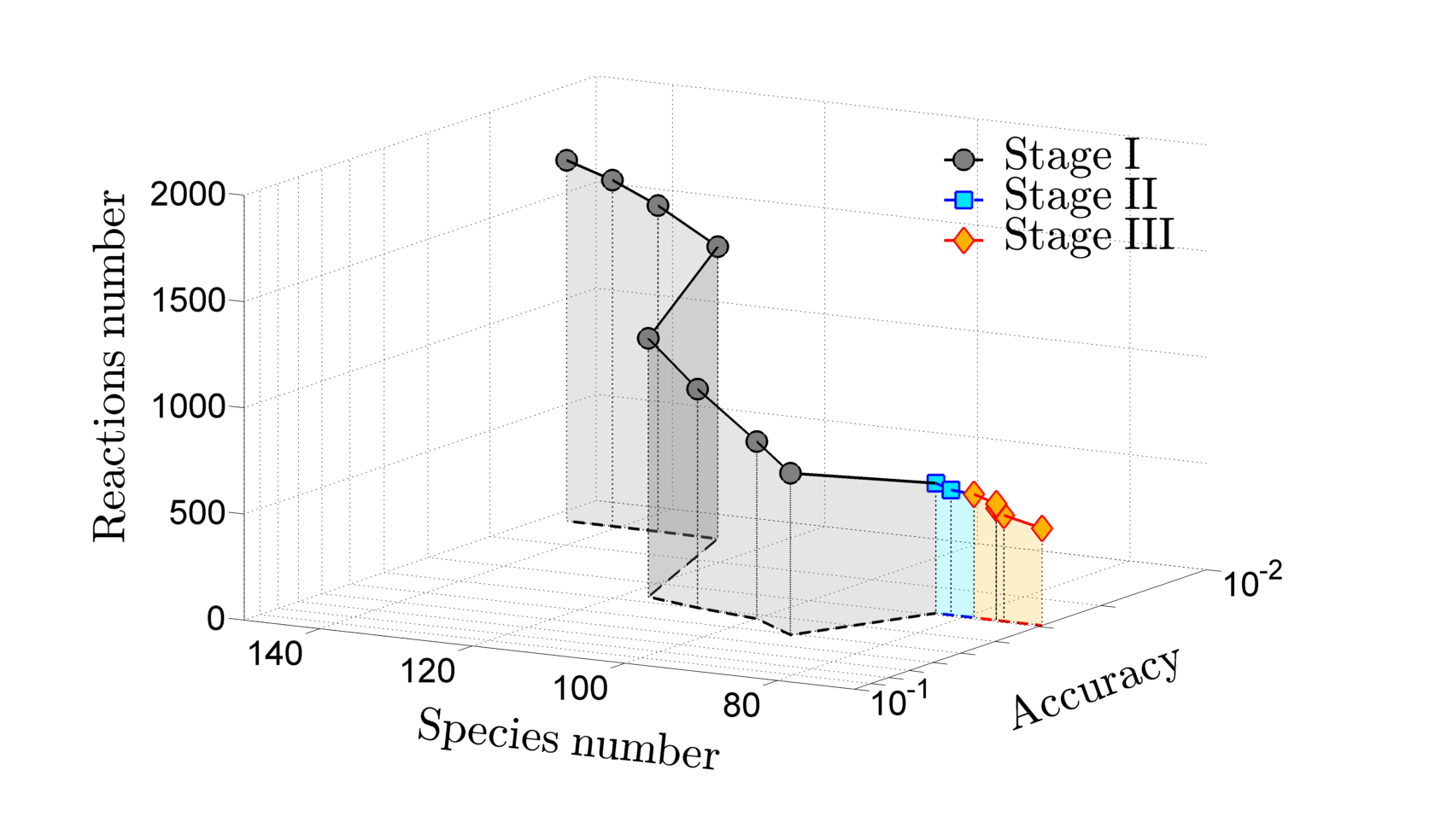

is observed. The subsequent elimination of unimportant species and reactions is achieved

via a three-stage reduction procedure. The first and second stages involve the Direct Relation

Graph with Error Propagation (DRGEP) method, whereas the third stage analyses rate

of progress of each reaction. The investigated conditions are taken from the experimental

studies of TEOS oxidation in oxygen-hydrogen flames. The final skeletal mechanism

comprises 70 species and 457 reactions and retains good reproduction of the key model

properties across the chosen operating conditions as compared to the full mechanism.

This paper improves the tetraethoxysilane (TEOS) oxidation mechanism proposed

by Nurkowski et al. (Proc. Comb. Inst., 35:2291-2298, 2015) by refining the rate parameters

of the key reaction channels in the mechanism. A skeletal version of the mechanism

is proposed for hydrogen-oxygen environment. The rates of ethylene-loss from

(tetra-, tri-, di- and dimethyldi-) ethoxysilane are computed using transition state theory.

The energetics of the main pathways are refined by performing detailed ab initio

calculations using the CBS-Q technique. An analysis of ethanol formation via silicates

is also performed resulting in the addition of 27 new silica species to the model. Thermodynamic

properties for these species are calculated via the balanced reactions method.

Reasonably good agreement between the improved model and available experimental data

is observed. The subsequent elimination of unimportant species and reactions is achieved

via a three-stage reduction procedure. The first and second stages involve the Direct Relation

Graph with Error Propagation (DRGEP) method, whereas the third stage analyses rate

of progress of each reaction. The investigated conditions are taken from the experimental

studies of TEOS oxidation in oxygen-hydrogen flames. The final skeletal mechanism

comprises 70 species and 457 reactions and retains good reproduction of the key model

properties across the chosen operating conditions as compared to the full mechanism.

Material from this preprint has been published in Combustion and Flame.

PDF (1.8 MB)