Simulation and life cycle assessment of algae gasification process in dual fluidized bed gasifiers

- Algae-derived syngas production using dual fluidised bed gasifiers is simulated.

- A global sensitivity analysis is performed to determine the impact of key input parameters on product yields.

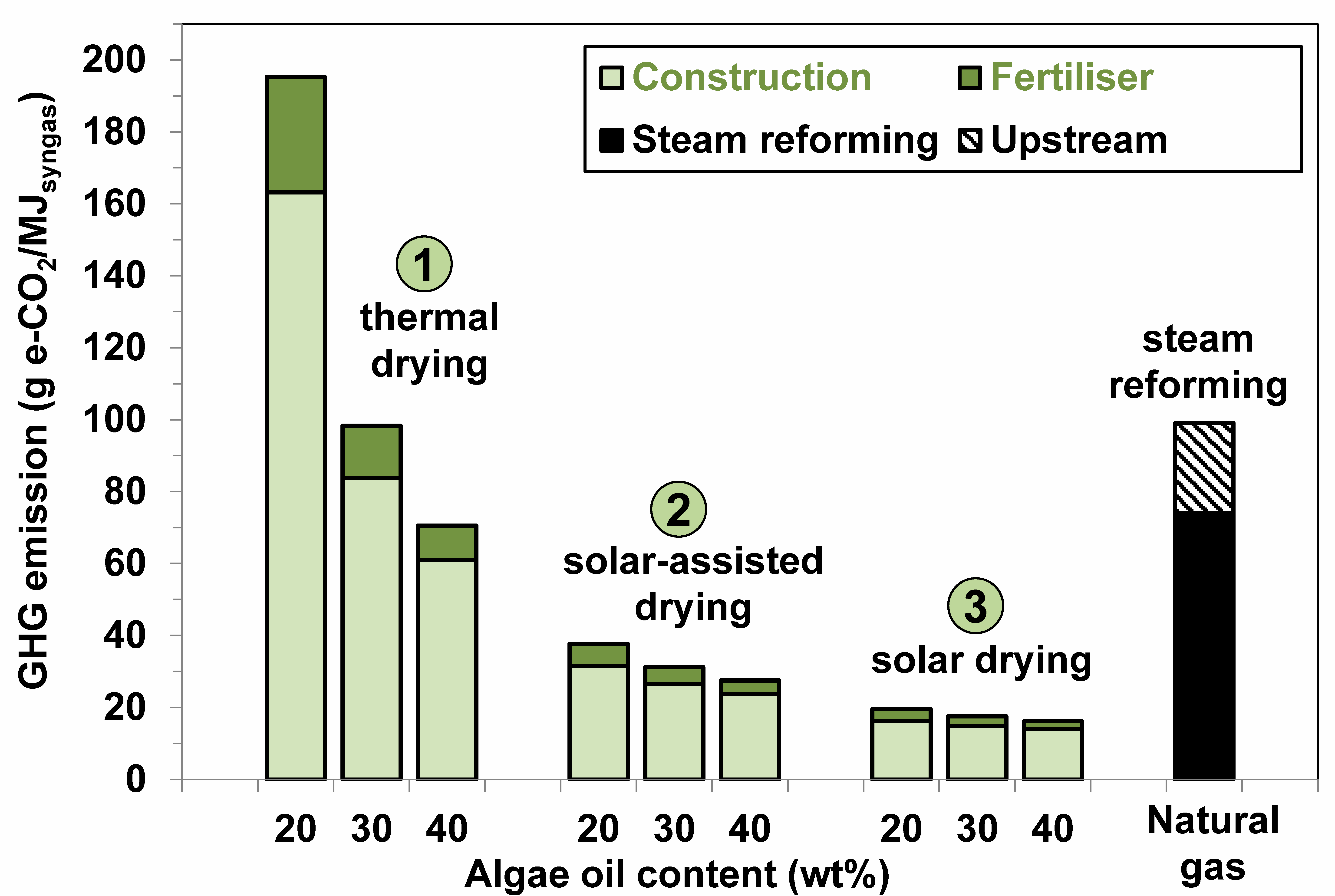

- Decarbonisation via solar energy reduces the carbon footprint to a value competitive with that of steam reforming of natural gas.

We present simulation results for the production of algae-derived syngas using dual fluidized bed (DFB) gasifiers. A global sensitivity analysis was performed to determine the impact of key input parameters (i.e. algae composition, gasification temperature, feed water content, steam-to-biomass ratio, and fuel-air equivalence ratio) on the product yields. The algae oil content was varied from 0 to 40 wt% to account for different algae strains and varying extents of oil extraction prior to the gasification process. It was found that the lower heating value (LHV) of syngas, typically ranging from 15 to 22 MJ/kg algae, is heavily dependent on the algae oil content. The cold gas efficiency (CGE) of the process varies over a range of 75 to 90%, depending primarily on the feedstock water content and steam-to-biomass ratio. A cradle-to-grave life cycle assessment indicated that the carbon footprint of syngas produced from algae feedstocks with 20 to 40 wt% oil fraction that is dried by a gas-fired dryer lies within a range of 70 to 195 g CO2/MJ. However, decarbonization of the drying stage via utilization of solar energy reduce the carbon footprint to values below 40 g CO2/MJ, which would compare favorably with the carbon footprint of syngas produced via steam reforming of natural gas (i.e. ~100 g CO2/MJ).

We present simulation results for the production of algae-derived syngas using dual fluidized bed (DFB) gasifiers. A global sensitivity analysis was performed to determine the impact of key input parameters (i.e. algae composition, gasification temperature, feed water content, steam-to-biomass ratio, and fuel-air equivalence ratio) on the product yields. The algae oil content was varied from 0 to 40 wt% to account for different algae strains and varying extents of oil extraction prior to the gasification process. It was found that the lower heating value (LHV) of syngas, typically ranging from 15 to 22 MJ/kg algae, is heavily dependent on the algae oil content. The cold gas efficiency (CGE) of the process varies over a range of 75 to 90%, depending primarily on the feedstock water content and steam-to-biomass ratio. A cradle-to-grave life cycle assessment indicated that the carbon footprint of syngas produced from algae feedstocks with 20 to 40 wt% oil fraction that is dried by a gas-fired dryer lies within a range of 70 to 195 g CO2/MJ. However, decarbonization of the drying stage via utilization of solar energy reduce the carbon footprint to values below 40 g CO2/MJ, which would compare favorably with the carbon footprint of syngas produced via steam reforming of natural gas (i.e. ~100 g CO2/MJ).

- This paper draws from preprint 144: Simulation and Life Cycle Assessment of Algae Gasification Process in Dual Fluidized Bed Gasifiers

- Access the article at the publisher: DOI: 10.1039/C4GC01698J