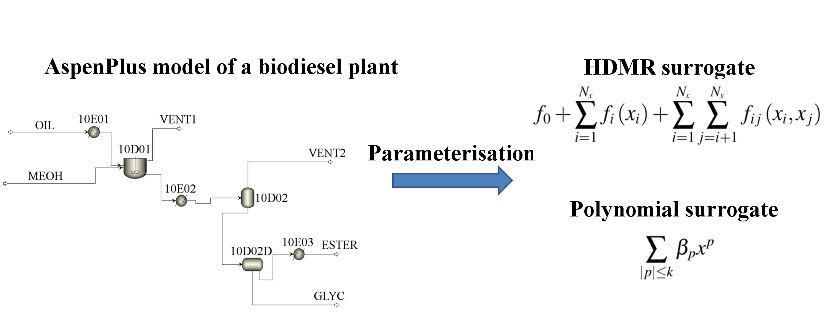

Parameterisation of a biodiesel plant process flow sheet model

- A process flow sheet of a biodiesel plant is described with two types of surrogate models: polynomial and High-Dimensional Model Representation (HDMR).

- Third order polynomial and HDMR surrogates achieve best and similar degree of accuracy.

- Polynomials of order higher than 3 suffer from overfitting, especially in high-dimensional scenarios.

- Global sensitivity analysis indicates that interaction terms have negligible effect on heat duties of the biodiesel plant.

This paper presents results of parameterisation of typical input-output relations within process flow sheet of a biodiesel plant and assesses parameterisation accuracy. A variety of scenarios were considered: 1, 2, 6 and 11 input variables (such as feed flow rate or a heater's operating temperature) were changed simultaneously, 3 domain sizes of the input variables were considered and 2 different surrogates (polynomial and high dimensional model representation (HDMR) fitting) were used. All considered outputs were heat duties of equipment within the plant. All surrogate models achieved at least a reasonable fit regardless of the domain size and number of dimensions. Global sensitivity analysis with respect to 11 inputs indicated that only 4 or fewer inputs had significant influence on any one output. Interaction terms showed only minor effects in all of the cases.

This paper presents results of parameterisation of typical input-output relations within process flow sheet of a biodiesel plant and assesses parameterisation accuracy. A variety of scenarios were considered: 1, 2, 6 and 11 input variables (such as feed flow rate or a heater's operating temperature) were changed simultaneously, 3 domain sizes of the input variables were considered and 2 different surrogates (polynomial and high dimensional model representation (HDMR) fitting) were used. All considered outputs were heat duties of equipment within the plant. All surrogate models achieved at least a reasonable fit regardless of the domain size and number of dimensions. Global sensitivity analysis with respect to 11 inputs indicated that only 4 or fewer inputs had significant influence on any one output. Interaction terms showed only minor effects in all of the cases.

- This paper draws from preprint 166: On the parameterisation of process flow sheet models

- Access the article at the publisher: DOI: 10.1016/j.compchemeng.2016.06.019