Spray Dryer Modelling

A new project in partnership with Proctor and Gamble (P&G) aims to produce a detailed model of a spray-drying tower. This simulation represents a typical application of our computational models and is the culmination of research into a number of disparate submodels including the CFD model (continuous phase), a coupled stochastic algorithm to solve the population balance equations (dispersed phase), and droplet drying models. It is hoped to incorporate detailed models for wall deposition and droplet fragmentation soon.

Spray drying towers are used across a wide range of industries; of particular interest to P&G are those they use to manufacture detergent powders. The operation of such units is dependent on the continuous phase, a macro-scale modelling problem, as well as the behaviour of the particles. Simulating these individual particles is a meso-scale modelling problem and requires some different computational techniques, namely the finite volume solution of partial differential equations with a coupled population balance on a moving spatial grid. The new particle-drying model currently under development will predict particle morphology, or ‘puffing’, alongside the spatially resolved moisture content and temperature.

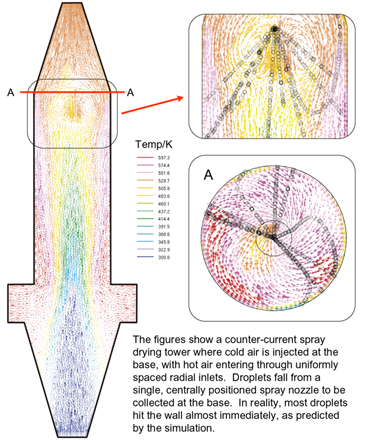

- Model validation conducted using a hierarchy of test geometries; the most sophisticated being a generic spray drying tower (pictured left)

- Figures represent a standard CFD solution to the Navier- Stokes equations in the Lagrangian/Eulerian framework, augmented with the k-epsilon model of turbulence

- Conservation equations for the continuous phase, expressed in Eulerian form, are suitably modified to take account of the presence of the dispersed phase (particle in cell method)

- Statistical approach used for the discrete phase: the total population is represented by a finite number of computational parcels tracked through the flowfield